MULTI-PLY BELLOWS CONSTRUCTION PROVIDES INCREASED PRESSURE AND MOVEMENT CAPABILITY

Triad Bellows strives for excellence when it comes to creating both standard and custom metal bellows capsules. With our state of the art tools, we are able to create a product that will exceed expectations and last for years. We create custom metal bellows capsules to make sure each specific case is addressed properly.

All of our products meet the EJMA guidelines and are specifically engineered for low pressure and high-pressure installations. Please give us a call to see how we can create the best stainless steel bellows capsule for you today.

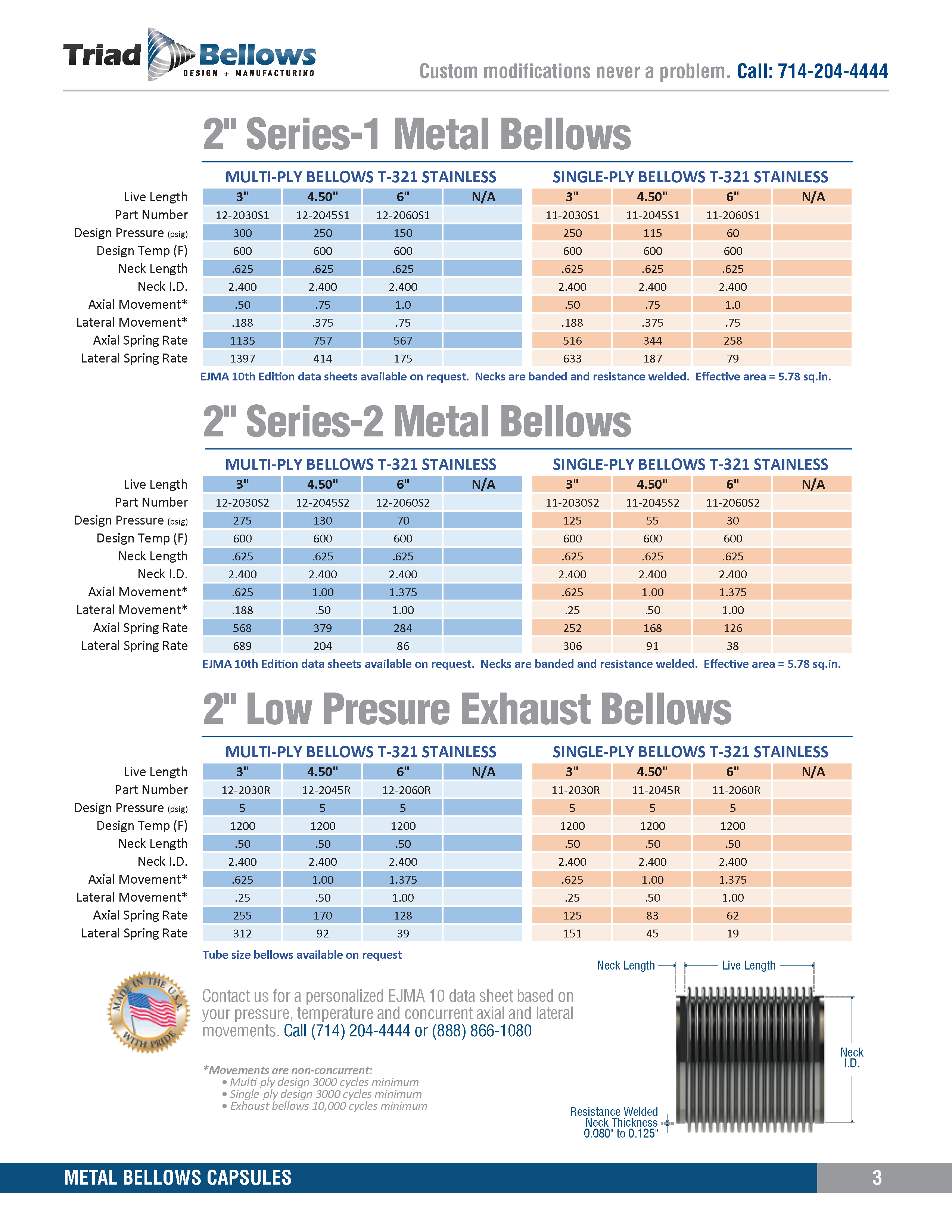

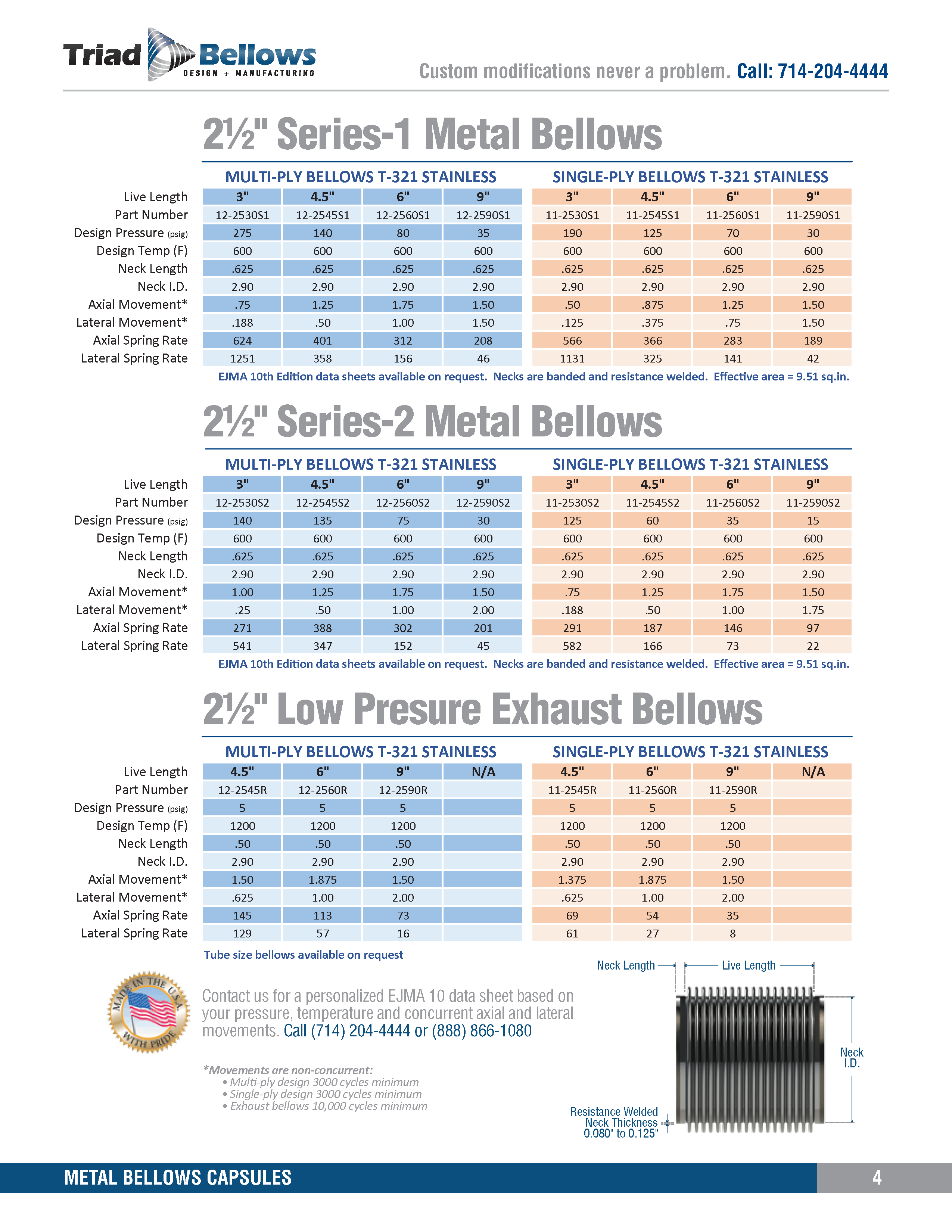

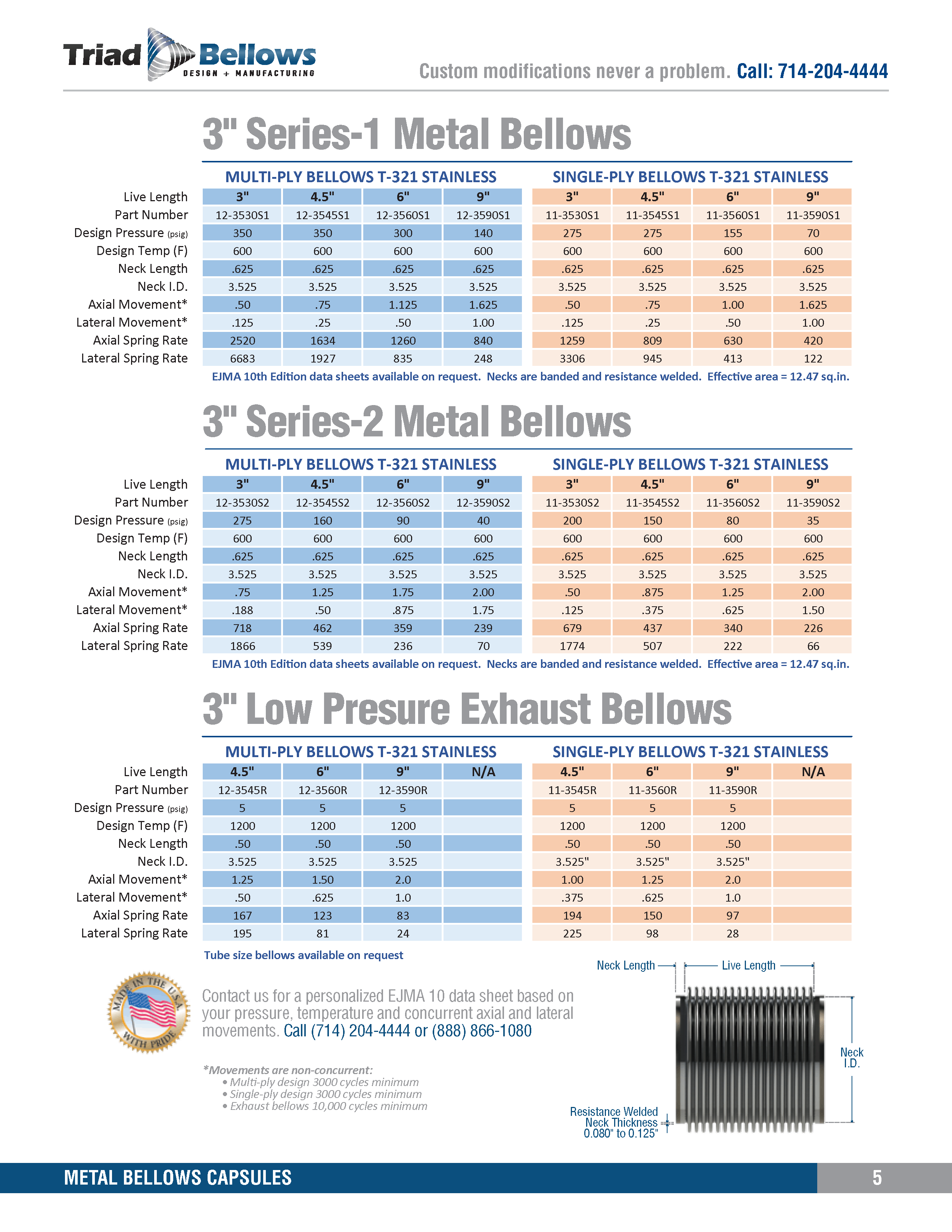

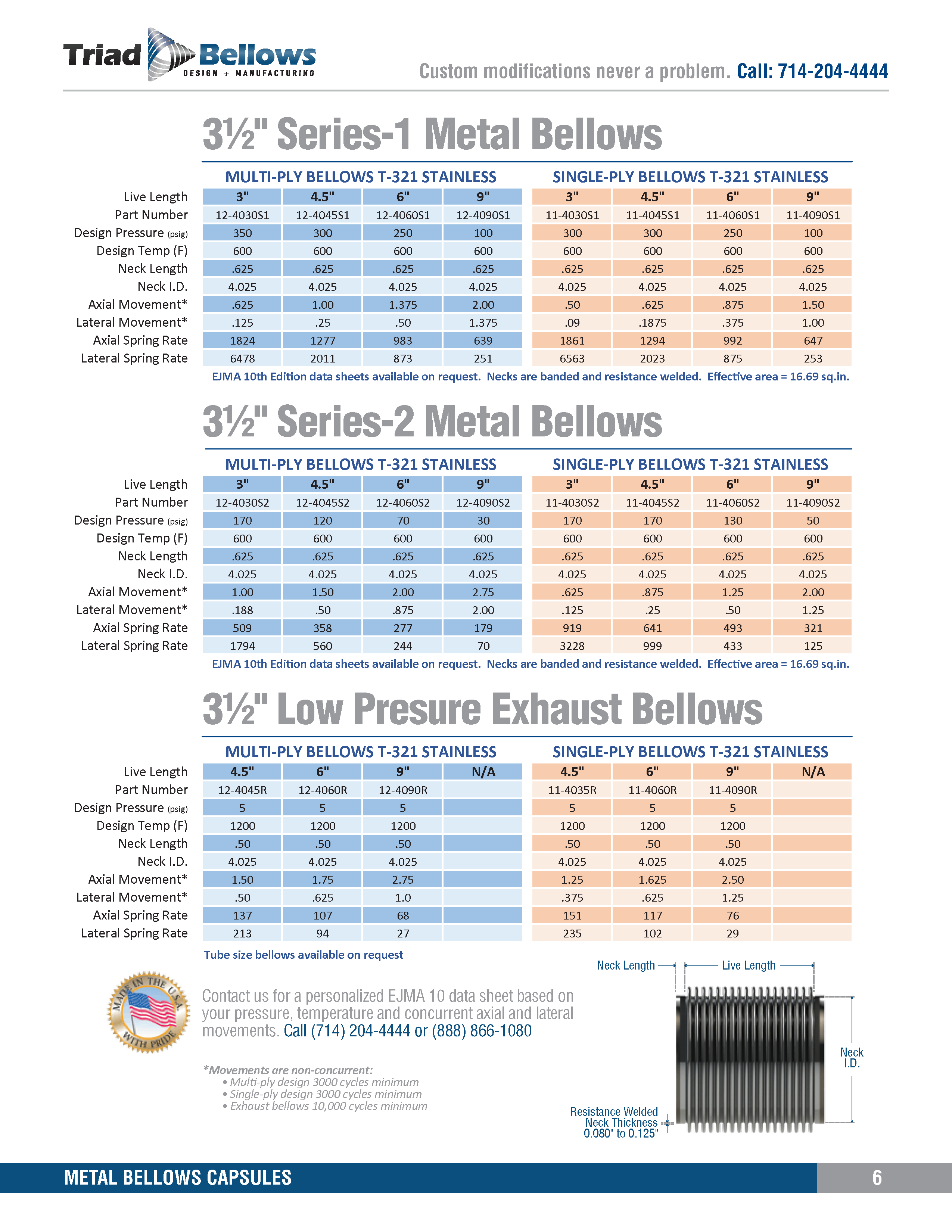

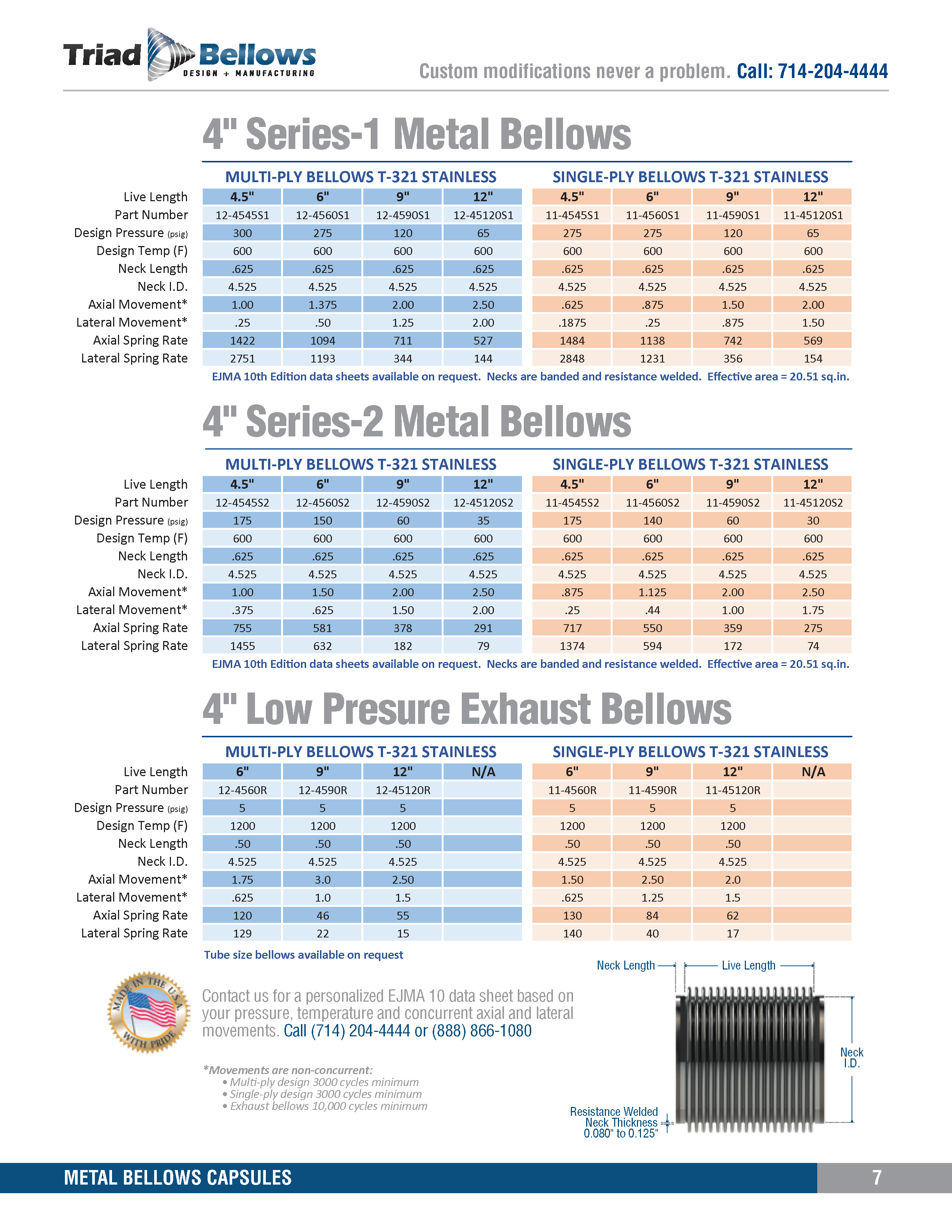

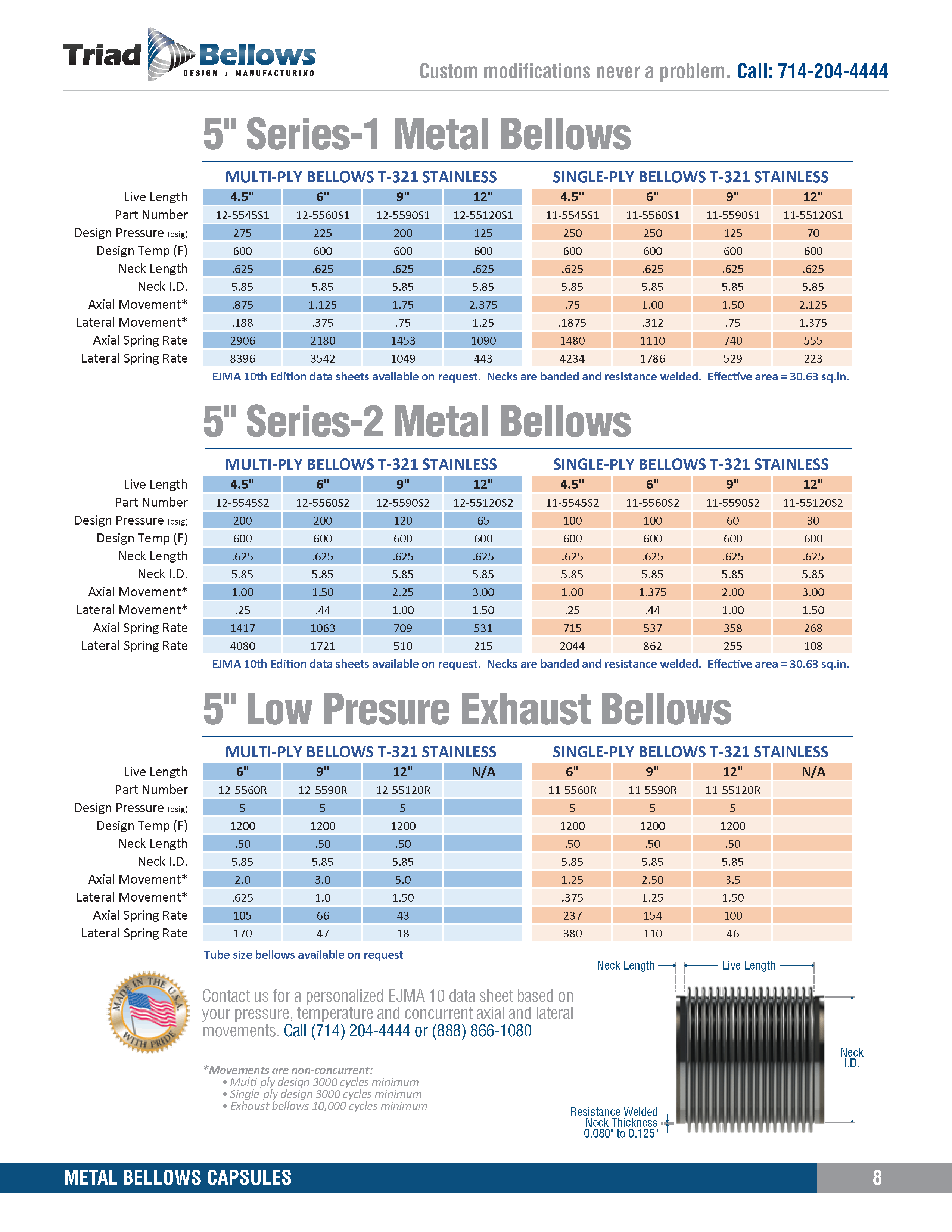

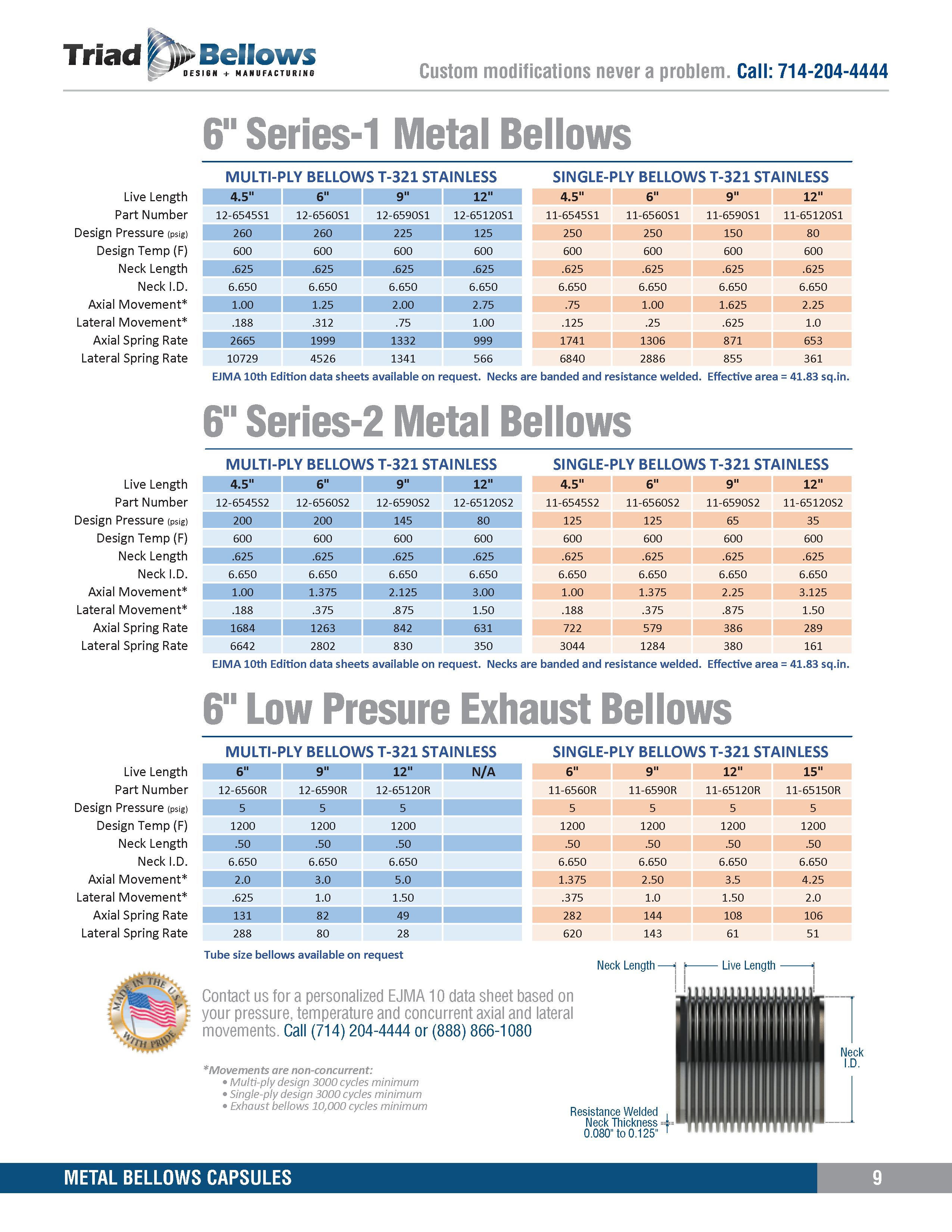

SERIES-1

Triad Bellows Series-1 metal bellows are manufactured with heavier gauge T-321 s/s to achieve higher pressure ratings. The allowable movements shown are based on a minimum of 3000 non-concurrent cycles. For lower pressure applications a Series-2 expansion joint will provide increased movement capability. When a standard metal bellows is not the right fit we will design and build a custom metal bellows perfectly designed for your application at a standard price.

SERIES-2

Triad Bellows Series-2 expansion joints are manufactured with lighter gauge T-321 s/s material to achieve greater movement capability while still maintaining a minimum of 3000 life cycles. When an even higher cycle life is required let us know and we will go to work designing the perfect metal bellows for your application. Our EJMA 10 design software allows us to combine just the right thickness and number of bellows plies needed to balance performance and cost savings.

Low Pressure Exhaust

Triad’s low-pressure bellows are engineered for a minimum 10,000 cycles. The high performance multi-ply design can absorb more thermal expansion in the piping system and is great for vibration isolation on reciprocating engines, turbines, fans, blowers etc… In addition to metal bellows Triad can furnish flow liners, vanstones and spacer tubes sized and fit to the bellows necks. As with all Triad Bellows products we can custom design and manufacture low pressure metal exhaust bellows quickly and economically