Metal bellows are very versatile as they can be made with different tensile, chemical, and physical properties. When making metal bellows in a bellow forming machine, there are a variety of materials you can choose from. Each material has its own advantages depending on the application of the bellows.

Brass bellows

Brass is a very popular material used when making metal bellows. It has a low manufacturing cost and pairs easily with today’s lead-free solders. Brass is usually used in applications that involve an air medium and can withstand temperatures up to 300 degrees Fahrenheit.

Bronze bellows

Bronze has a slightly higher tensile strength, better corrosion resistance, and better electrical conductivity compared to brass. It still offers a low manufacturing cost, though. Bronze solders easily like brass, but it can be brazed for use in high-temperature applications. Often, brass bellows are used for applications like appliances and HVAC equipment.

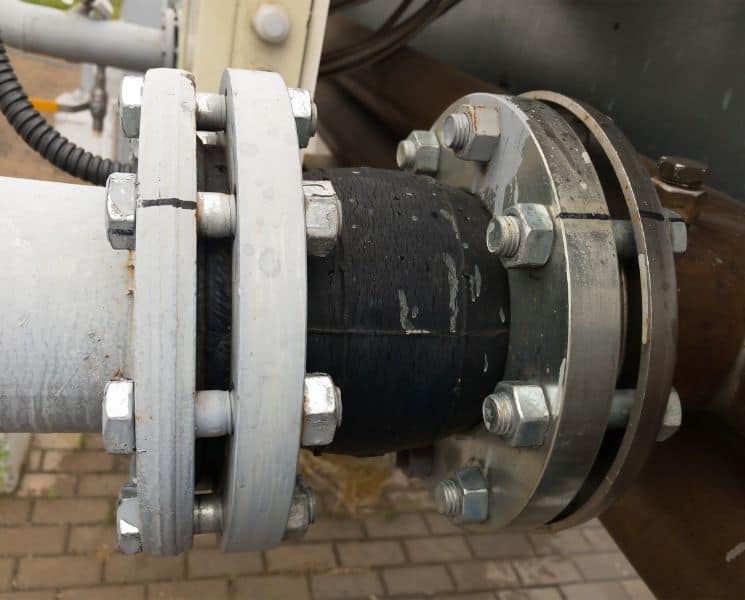

Stainless steel bellows

When forming metal bellows of stainless steel, there are a variety of stainless steels you can choose from with different properties. For example, Forged steel 150# flanges are rated for pressures up to 285 psig at 100 degrees Fahrenheit, and the allowable pressure is reduced to 65 psig at 850 degrees. Stainless steels have excellent tensile strength, corrosion resistance, and high-temperature withstanding properties. Stainless steel bellows are often used in electrical interrupters, power transmission systems, and industrial controls.

Nickel bellows

Nickel is a very hard material that has excellent corrosion resistance. Electro-deposited bellows and corrosion-resistant planting bellows are made from nickel. Nickel also has a wide range of tensile strength and is used in many aerospace applications.

Monel bellows

Monel is a nickel alloy that has high corrosion resistance. Monel is often welded, but it can be brazed as well. Because of its mechanic performance, it is often used in corrosive environments like containing steam from salt water.

Beryllium Copper bellows

This material is ideal when it comes to seamless metal bellows. Beryllium copper has a superior electrical conductivity and tensile strength when compared to other materials used for making metal bellows. It can be either soldered or brazed. This material is used when applications require a small package size and a demanding life cycle, like aerospace systems and instruments.

When making metal bellows, you have six basic materials to choose from, all with different properties. Your choice will depend on the application needed for the bellows. For more information, give us a call today.