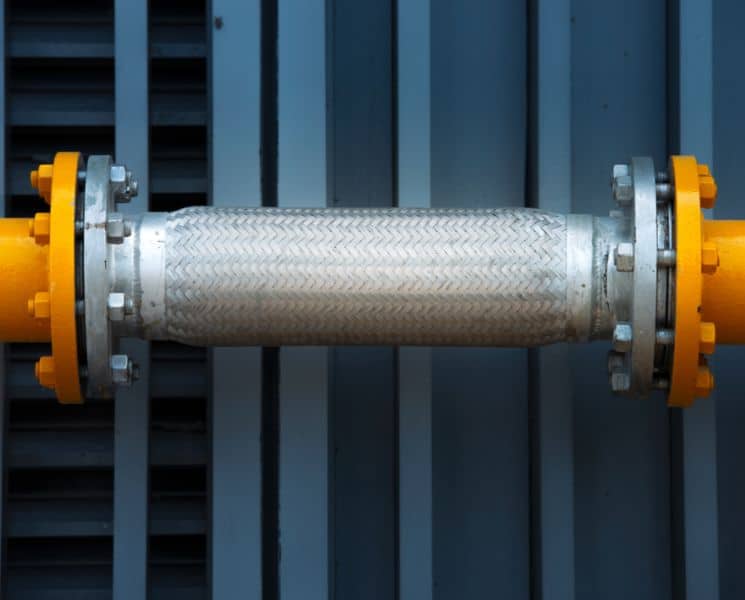

Custom Bellows Forming Equipment designed for accuracy and cost savings.

Every step of the bellows forming process has been carefully planned to meet our lean manufacturing goals. The same careful planning has gone into the design of our custom manufactured bellows equipment. The result is an extremely accurate product at very competitive prices.

Our automated bellows formers use a controlled 12 step and 16 step process to shape each convolution. This process takes longer than manual bellows punching but material thinning is almost eliminated. The bellows convolutions at Triad are always evenly spaced, straight and scratch free.

Leave A Comment