What can bellows be made of?

What can bellows be made of? Well, metal bellows specifically can be made of a variety of metal alloys, including brass, bronze, nickel, Monel, beryllium copper, and stainless steel. When it comes to marine environments, stainless steel is usually the best choice. The main reason for that is because it does not rust.

Bellows that are made of stainless steel are usually a standard mixture of iron, carbon, chromium, and nickel so that the steel does not rust. It can’t rust because for steel, the iron and oxygen mixture that usually causes rust can’t resist each other and bond to make a surface film of iron oxide. Additionally, in order to resist the corrosive effects of salt in marine environments, Marine Grade Stainless Steel alloys typically contain molybdenum, which is an element with the atomic symbol of 42 and a melting point of 4,748 degrees Fahrenheit.

How are stainless steel bellows used in ships?

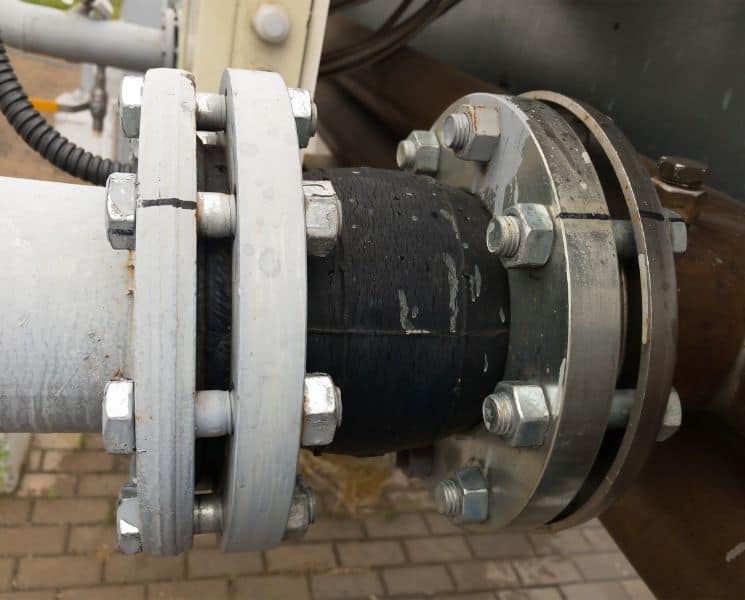

Stainless steel bellows and expansion joints, plus metal hoses, are used for new ships as well as maintenance and refurbishing for repair. Here are some of the major applications:

- Expansion joints are used for turbines and engine exhaust systems.

- Expansion joints and metal hoses are used for the transfer of oil, water, and air or steam.

- Expansion joints and metal hoses are also used for vapor recovery and fluid transfer applications.

- While expansion joints are typically used for vapor recovery and fluid transfer applications, they can also be developed to meet a customer’s specific requirements.

When it comes to exhaust bellows for a ship, they are specifically designed to operate in the “elastic range” of the metal so that they can resist hardening and cracking as a result of long-term exposure to vibration. They are also designed to accommodate the fundamental natural frequencies during the engine startup and to avoid the natural frequency signature of engines in their normal operating range.

Stainless steel bellows are incredibly important for a ship’s engine because they not only help it run efficiently, but they can extend the life of it as well because it can resist the harsh sea environment.