Pipe systems expand and contract when the temperature around them changes. Whether caused by the external environment or the internal fluids that pass through pipes, these temperature changes are frequent. Engineers must plan for these expansions and contractions during the design phase to mitigate the potential damage this causes. Pipe length and material affect the degree of change, but there are also several additional measures engineers can take. If you’d like to learn how to account for thermal expansion in piping system design, consider implementing one of these deflection mechanisms.

Deflection Mechanisms

The goal of these deflection mechanisms is to increase pipes’ overall flexibility. By flexibility, we mean pipes’ capacity to shift to accommodate increases in pressure. It’s crucial to make sure your pipes are not rigid enough to crack but not so flexible that they decrease your transfer efficiency. There are several methods for deflecting pipe fluids to maximize pipe flexibility and prevent failure, two of which are expansion loops and expansion joints.

Expansion Loops

Expansion loops are common interventions meant to account for thermal expansion in piping systems. Rather than guiding pipes in a straight line, engineers implement U-shaped pipe sections that allow for more give when pipes experience thermal change. By “give,” we mean that when the entire pipe system contracts when cooling, the piping on each side of the U loop has the space to pull the U open. Alternatively, when pipes expand, the pipes can take advantage of the flexible space between the U loop and push it closed.

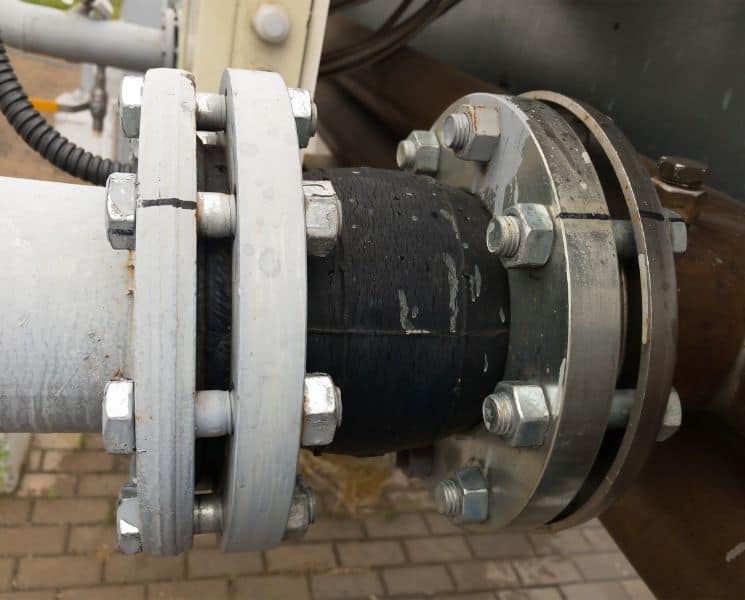

Expansion Joints

A second deflection option is to install expansion joints. These joints take up less space than expansion loops because, rather than increase flexibility through more piping, they employ bellows that enable the joints themselves to expand and contract to accommodate thermal changes. It’s important to anchor these expansion joints to something secure to take full advantage of these structures. There are many types of expansion joints for different purposes, even including pressure balanced joints for situations when where you cannot anchor your joint. If you would like to implement expansion joints in your piping system design, contact our Triad Bellows team. We offer many types of expansion joints, including high temperature expansion joints made with a special alloy to maintain pipe performance in extremely high temperatures.