Metal bellows are like elastic vessels that have the ability to be compressed when pressure is applied. They then re-expand back to their original shape when the pressure is off. They also extend when under a vacuum, and of course, go back to their original shape when the vacuum is released.

The key component of metal bellows is that they are flexible. This balance can be hard to achieve because they also must be strong enough to withstand the pressure that is applied. The application meant for the bellow will determine how the balance is distributed. In other words, some bellows are more flexible than they are strong, and vice versa, depending on their intended use.

What are Bellows Used for?

After now understanding the properties of a metal bellow, you may be wondering, what are bellows used for? Machine Design gives us some applications of this device. Several processes require the use of the metal bellow.

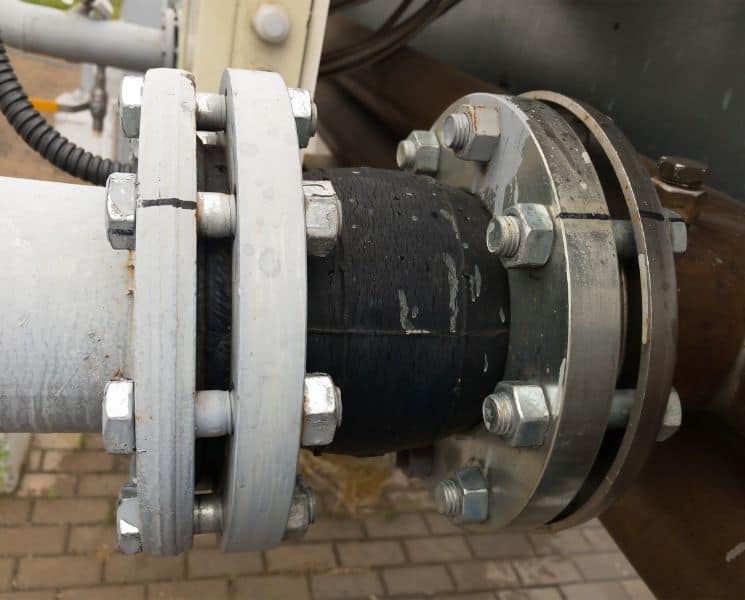

According to the Machine Design, “they find use as metallic hermetic seals, volume compensators, pressure and temperature sensors, flexible connectors, and in myriad other applications where high quality and long life are critical requirements, such as in the aerospace industry.” Because these metal bellows have the ability to be incredibly diverse, there are several different specialized types, meaning custom bellows are popular.

Types

Custom bellows are designed with application in mind. According to Machine Design, there are 12 different attributes that need to be taken into consideration when a bellow is manufactured, whether it is for standard bellows or exhaust bellows. Here are just a few.

The first thing that needs to be considered, as previously mentioned, is how much stress is the bellow going to be under. The manufacturer needs to know how strong the bellow needs to be so that it will not break during use.

Flexibility, also needs to be taken into account when the bellow is designed. The unique balance of each of the custom bellows is determined by the job being preformed. If it is more important the the bellow is flexible than strong, then the bellow will be designed in that way.

Pressure is the third factor to take into consideration when designing custom bellows. The pressure on the external versus internal structure of the bellow is an important attribution to understand so they the bellow can handle the job it is designed to do.

If you are working with bellows, are new to bellows, or just want to know more about them, this guide should be a good start.