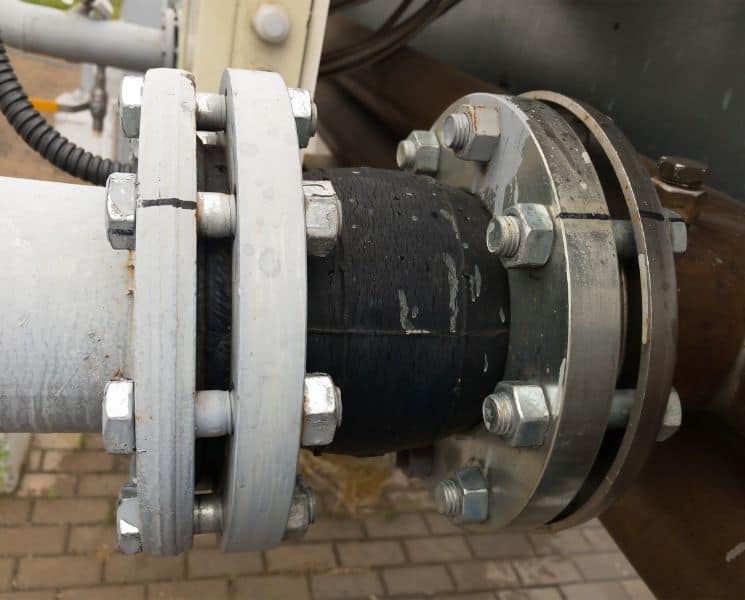

There are so many materials on a construction site, but perhaps the most overlooked pieces of equipment are expansion joints. This article will discuss the role of pipe expansion joints in construction and prove that they’re invaluable tools in the industry.

Thermal Expansion

Thermal expansion joints help a pipe grow as the temperature increases. It’s critical to have these devices on a construction site because gases and hot water often run through a piping system. As a result, these components are necessary to ensure nothing cracks, and workers do a good job completing the project.

Stresses & Shock

Another advantage of using pipe expansion joints in construction is that they absorb stress and shock. The components expand when they’re under pressure so they can withstand the weight of a foundational structure. The parts can also absorb unexpected shockwaves that occur at a construction site. Pipe expansion joints can handle pipe cavitation or the aftereffects of a power surge. Accordingly, building manufacturers must use these parts when designing a new structure.

Corrosion

In construction, expansion joints can also reduce corrosion. However, officials must ensure the materials match up to prevent this from happening. If the joints and pipes are made from the same material, it’s less likely for rust to build up. Furthermore, these components limit misalignment. When the joint grows, pipes line up more perfectly instead of cracking, which may cause a leak.

Noise

One of the final reasons why construction workers should use expansion joints on their projects is because they absorb noise. The parts soak up sound transmissions as they expand, making them less noisy than other components. Minimizing noise in a construction zone is more valuable than many people realize. Construction workers could put their safety at risk if a project is too loud, or may make things incorrectly due to loud, noisy distractions.

This piece has shown that there are many benefits of using pipe expansion joints in construction. Above all else, the components are adjustable to external factors. Since they alter themselves based on temperature and stress levels, they’re important to have on construction sites.