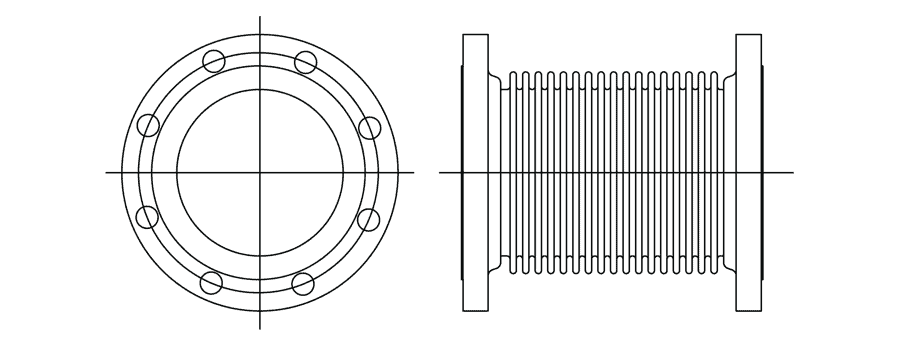

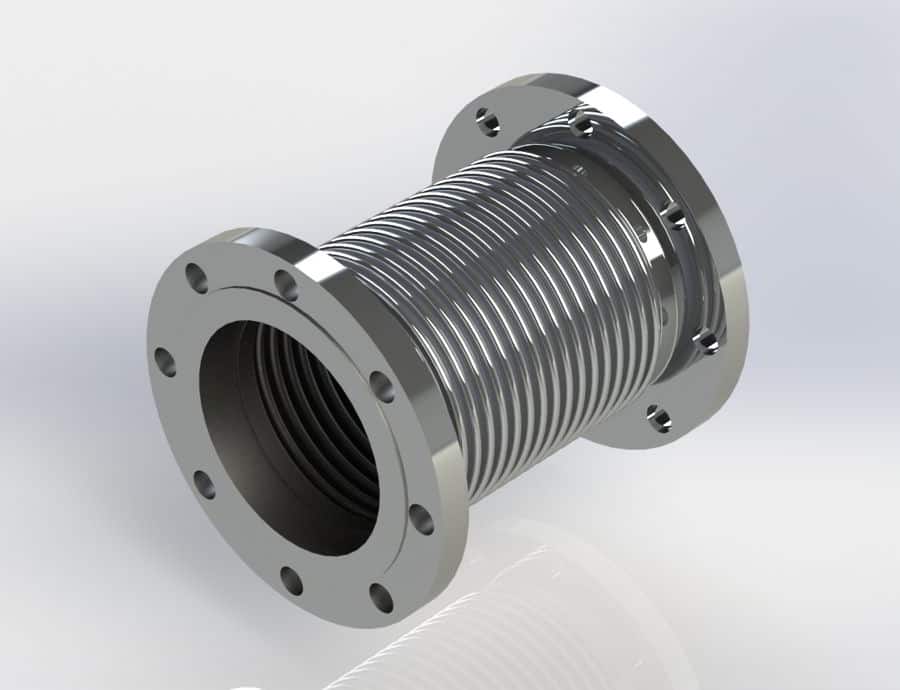

STAINLESS STEEL EXPANSION JOINTS

Our low pressure and high pressure custom metal expansion joints are designed and manufactured in strict accordance with the Expansion Joint Manufacturers Association (EJMA) latest 10th edition. At Triad Bellows we believe that design integrity is key to building metal bellows expansion joints that will last. Customers around the world rely on TBD&M for dependable stainless-steel expansion bellows and expansion joint products engineered for maximum fatigue cycle life.

With the high costs associated with system downtime, why settle for a generic stainless steel expansion joint when you could have the design team at Triad Bellows engineer your metal expansion bellows for the ultimate performance, with no additions cost or manufacturing time. To get started, head on over to our catalog page to scope out our complete selection of custom metal bellows and more.

Triad Bellows Stainless Steel Expansion Joints – Custom Designed and Manufactured

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| MEDIUM |  Axial Axial |

MEDIUM |

| MEDIUM |  Lateral Lateral |

MEDIUM |

| LOW |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 110″ |

|

Temperature Range: -400º F up to 1500ºF |

|

Pressure Range: Full Vacuum to 750 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | YES |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

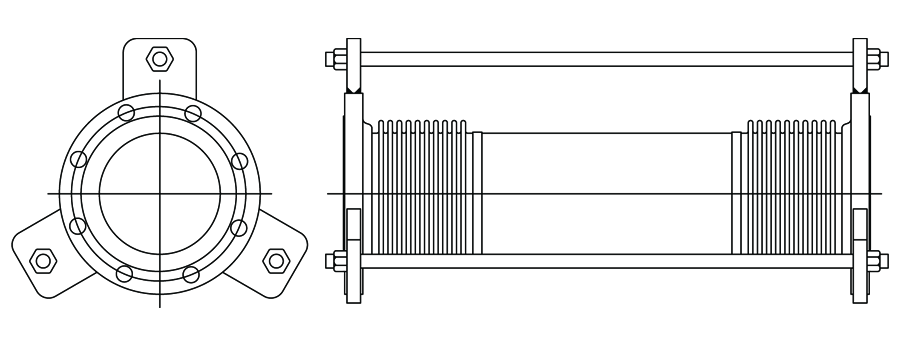

In-Line Pressure Balanced Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| MEDIUM |  Axial Axial |

MEDIUM |

| LOW |  Lateral Lateral |

MEDIUM |

| NONE |  Angular Angular |

NONE |

|

Diameter Range: 2″ – 24″ |

|

Temperature Range: -400º F up to 850ºF |

|

Pressure Range: Full Vacuum to 150 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | NO |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

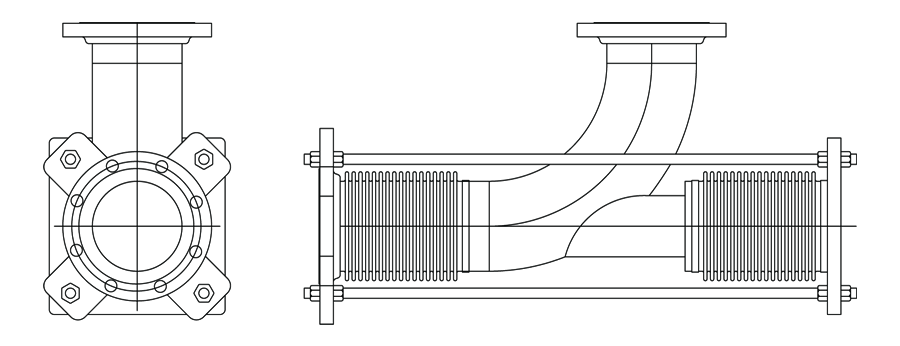

Elbow Pressure Balanced Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| MEDIUM |  Axial Axial |

MEDIUM |

| HIGH |  Lateral Lateral |

LOW |

| LOW |  Angular Angular |

HIGH |

|

Diameter Range: 2″ – 24″ |

|

Temperature Range: -400º F up to 850ºF |

|

Pressure Range: Full Vacuum to 150 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | INCLUDED |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

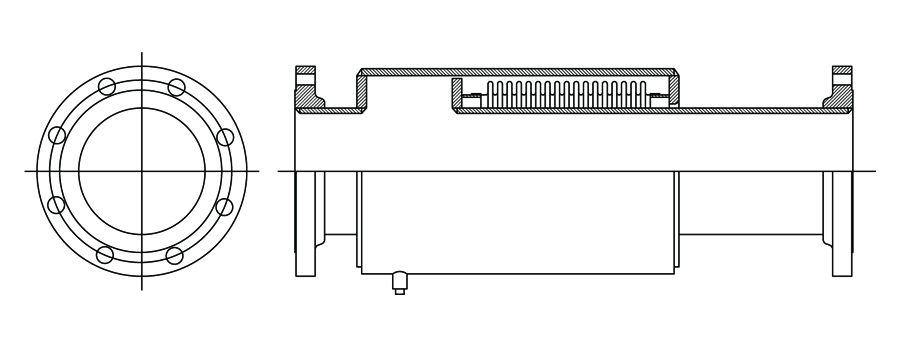

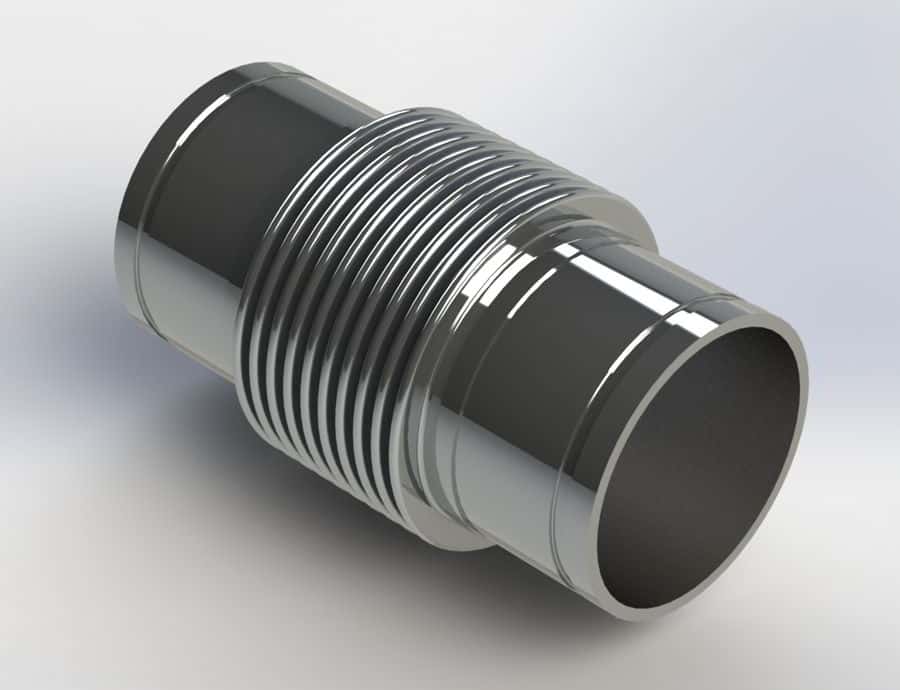

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| HIGH |  Axial Axial |

MEDIUM |

| NONE |  Lateral Lateral |

NONE |

| NONE |  Angular Angular |

NONE |

|

Diameter Range: 2″ – 24″ |

|

Temperature Range: -400º F up to 850ºF |

|

Pressure Range: Full Vacuum to 300 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | NO |

|

FLOW LINERS | INCLUDED |

|

SHROUDS / COVERS | INCLUDED |

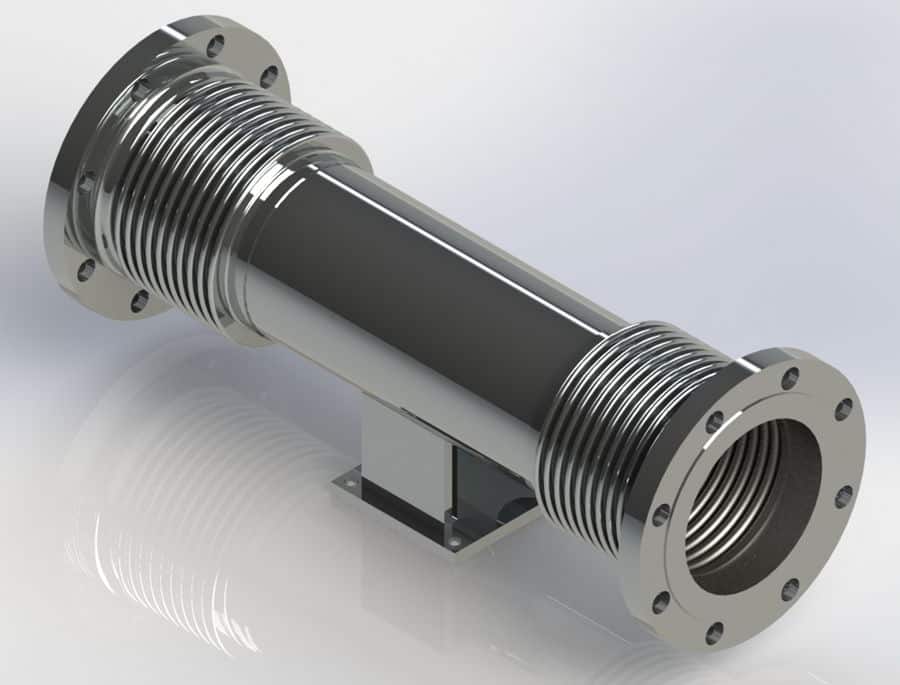

Universal Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| MEDIUM |  Axial Axial |

MEDIUM |

| HIGH |  Lateral Lateral |

LOW |

| MEDIUM |  Angular Angular |

HIGH |

|

Diameter Range: 2″ – 60″ |

|

Temperature Range: -400º F up to 1500ºF |

|

Pressure Range: Full Vacuum to 750 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | YES |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

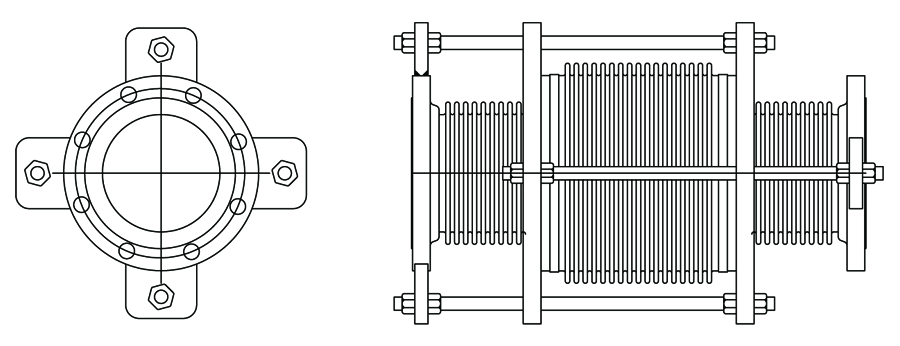

Tied Universal Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| NONE |  Axial Axial |

NONE |

| HIGH |  Lateral Lateral |

LOW |

| LOW |  Angular Angular |

HIGH |

|

Diameter Range: 2″ – 60″ |

|

Temperature Range: -400º F up to 850ºF |

|

Pressure Range: Full Vacuum to 300 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | INCLUDED |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

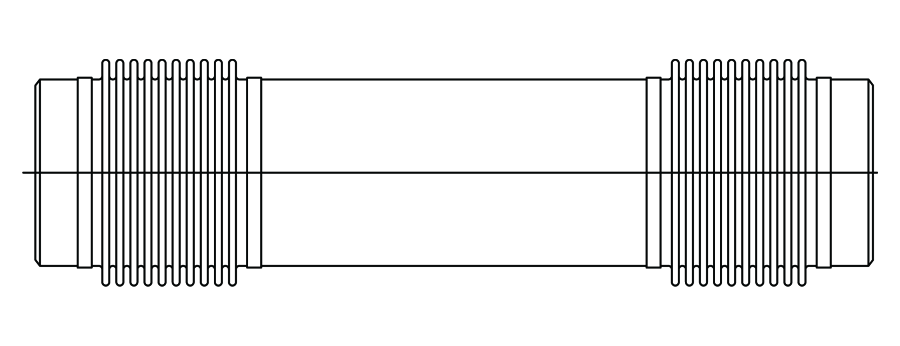

Dual Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| HIGH |  Axial Axial |

MEDIUM |

| LOW |  Lateral Lateral |

HIGH |

| LOW |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 60″ |

|

Temperature Range: -400º F up to 1500ºF |

|

Pressure Range: Full Vacuum to 750 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | NO |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

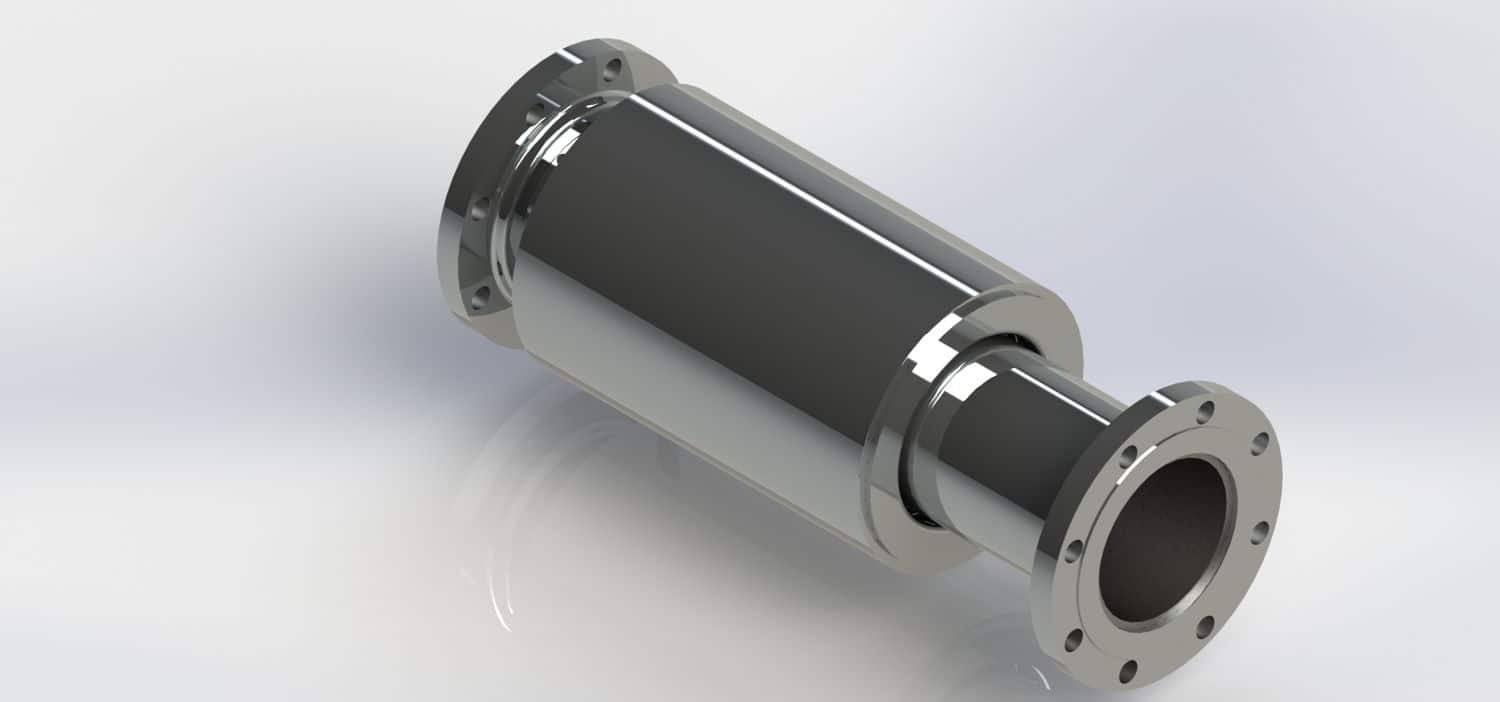

Pump Connectors with Tie Rods

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| LOW |  Axial Axial |

MEDIUM |

| LOW |  Lateral Lateral |

HIGH |

| LOW |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 24″ |

|

Temperature Range: -400º F up to 700ºF |

|

Pressure Range: Full Vacuum to 300 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | INCLUDED |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

Victaulic Groove Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| MEDIUM |  Axial Axial |

MEDIUM |

| LOW |  Lateral Lateral |

HIGH |

| LOW |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 24″ |

|

Temperature Range: -400º F up to 700ºF |

|

Pressure Range: Full Vacuum to 300 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | YES |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

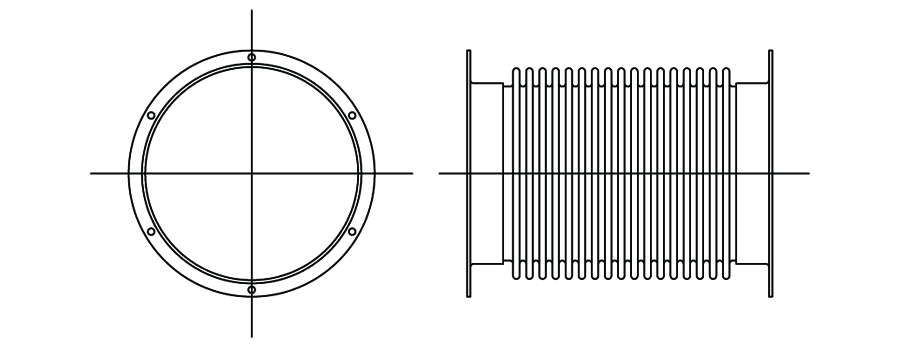

Hinged Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| NONE |  Axial Axial |

NONE |

| NONE |  Lateral Lateral |

NONE |

| MEDIUM |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 48″ |

|

Temperature Range: -400º F up to 700ºF |

|

Pressure Range: Full Vacuum to 300 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | NO |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | NO |

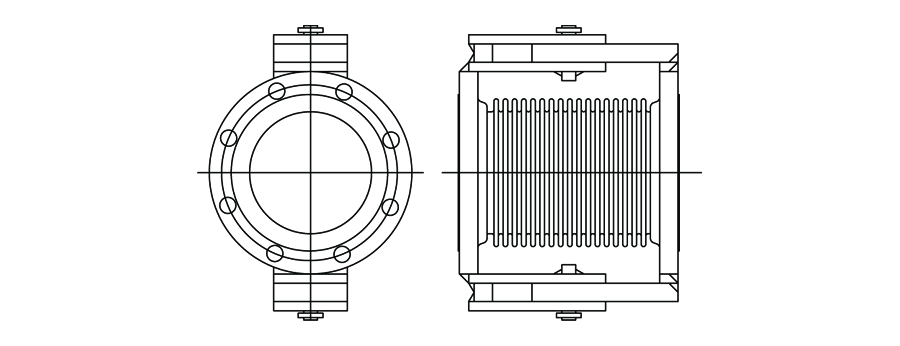

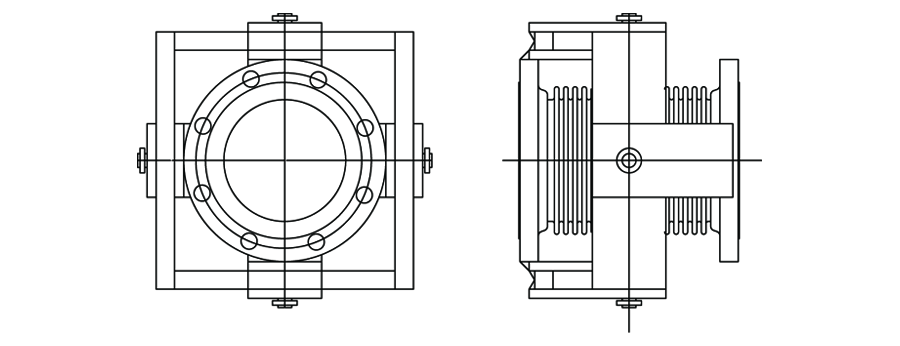

Gimbal Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| NONE |  Axial Axial |

NONE |

| NONE |  Lateral Lateral |

NONE |

| MEDIUM |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 48″ |

|

Temperature Range: -400º F up to 700ºF |

|

Pressure Range: Full Vacuum to 300 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | NO |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | NO |

Metal Duct Expansion Joints with Angle Iron Flanges

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| HIGH |  Axial Axial |

LOW |

| MEDIUM |  Lateral Lateral |

LOW |

| HIGH |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 110″ |

|

Temperature Range: -400º F up to 1500ºF |

|

Pressure Range: Full Vacuum to 15 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | YES |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

Large, Low Pressure Blower and Fan Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| HIGH |  Axial Axial |

LOW |

| MEDIUM |  Lateral Lateral |

LOW |

| HIGH |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 110″ |

|

Temperature Range: -400º F up to 1500ºF |

|

Pressure Range: Full Vacuum to 15 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | YES |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |

Rectangular Metal Expansion Joints

| MOTION CAPABILITY |

SPRING FORCES |

|---|

| HIGH |  Axial Axial |

LOW |

| MEDIUM |  Lateral Lateral |

LOW |

| HIGH |  Angular Angular |

LOW |

|

Diameter Range: 2″ – 110″ |

|

Temperature Range: -400º F up to 1500ºF |

|

Pressure Range: Full Vacuum to 15 PSIG |

| AVAILABLE ACCESSORIES | ||

|

TIE RODS / LIMIT RODS | YES |

|

FLOW LINERS | YES |

|

SHROUDS / COVERS | YES |