In industries where precision and performance are highly regulated and monitored to ensure efficient production, the smallest variables are taken into account. Some of these industries include marine, oil and natural gas, solar power, manufacturing and processing, and even engine and generator. These industries rely on the performance of all parts, down to the stainless exhaust flex joint.

In order to test the quality of parts, specifically components like metal bellows and things of that nature, manufacturers will often use indicators such as a hydro test.

What Is a Hydro Test?

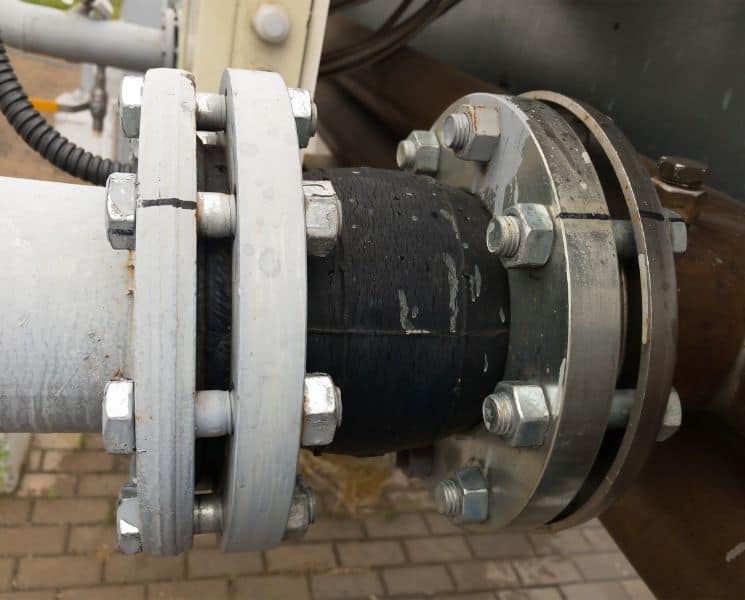

Hydrostatic testing (also referred to as hydro testing) is the process of using pressure to determine the integrity of a specific component. Parts such as multi-ply bellows, which generally consists of two to three tubes but can have as many as five, are often subject to hydrostatic testing.

How Does Hydro Testing Work?

Consider a stainless exhaust flex joint, for example. The joint would be filled with water, and then the air would be removed from inside the component to create a vacuum. The test administrator would then increase the pressure within the stainless exhaust flex joint up to 1.5 times the specified design pressure limit. The pressure would be held for a period of time, during which the administrator would check for leaks and faults. This process can be made easier by adding tracer or fluorescent dye to the water to better identify the source of the leak(s). If there is no evidence of a leak, the component passes the test and is considered to have enough integrity to be used in the intended application.

Is There More Than One Method?

Yes, there are three common hydro testing methods used for pressure vessels and cylinders. They are the water jacket method, the direct expansion method, and the proof pressure method. However, the proof pressure method is only allowed in the U.S. if expansion values don’t need to be recorded. Also, certain components are not able to withstand a hydro test, and other tests will need to be used to determine integrity.

Depending on the industry, the component being tested will vary and in some cases, the fluid might be problematic. Oil and gas pipelines should be thoroughly cleaned and dried after a hydro test is completed due to a high risk of corrosion associated with using water. Using this test will help identify any faults, and ensure components operate as they should.

Need custom bellows? Contact us today.