Seamless hydroformed bellows

As the name suggests, seamless metal bellows don’t have any welded joints. They are instead produced in a multi-step, deep-drawing process that forms the convolutions. This process can withhold extremely accurate and consistent dimensions. Because seamless bellows are drawn and formed, they avoid the potential risk of leak paths and internal stresses of welded joints.

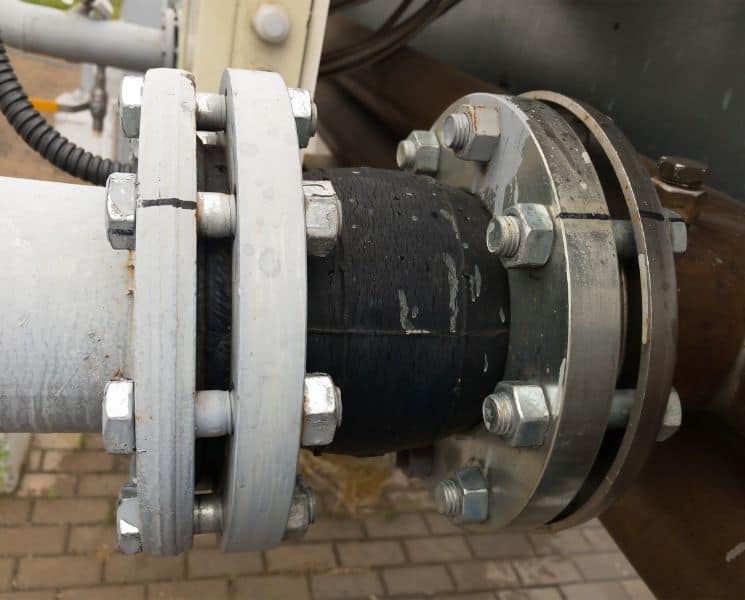

Seam-welded formed bellows

These bellows are made from welded, rolled, and formed sheet-metal stock. They can be made in large diameter and at any required length. Because of the large size, though, they do not lend themselves to applications that need a precise spring rate. The production of these bellows is cost-effective, and they are often used for expansion joints and other connections that compensate for the movement of mating components.

Edge-welded bellows

Stamping and welding are both required steps for metal bellows manufacturing when they are edge-welded bellows. The stamping process turns out a set of ring-shaped diaphragms. Then, the diaphragms are joined with welds along the outer and inner diameters. These bellows are typically used in applications that include aircraft engines, semiconductor equipment, and medical devices because they can be used in applications where the size of the package is at a premium and cost doesn’t matter as much.

Electro-formed bellows

These bellows are formed by the electro-deposition of nickel onto an aluminum mandrel. They do not experience the same geometry limitations of welded or formed bellows. They have little variation of wall thickness, diameters, or convolution shape. This allows the manufacturer to fine-tune stroke, spring rate, and mean effective area. They are also very compact. These bellows normally see low-volume, high-performance applications like defense and aerospace.

There you have it, the main steps for mental bellows manufacturing methods. According to the Solar Energy Industries Association, American installed 2,387 megawatts of new solar power capacity in a near-record Q2 2017. The solar power industry, as well as other high-tech, essential industries, rely on metal bellows to help get the job done.