There are many applications for custom bellows in particular, as every bellows has its own unique job and setting. There are 12 attributes that go into manufacturing custom bellows, and each attribute will depend on the intended purpose of the bellows. Here are those 12 attributes briefly explained.

- Stress Modes: The amount and type of stress the bellows will experience will affect the manufacturing process. Extension, compression, speed of rotation, and torque are all attributes of stress modes for custom bellows.

- Quantify Flexing: The maximum amount of stroke, or axial compression/extension, should be specified. The more or less flexible the bellows will be depends on the needed bend of the piece.

- Pressure Differential: The bellows will experience different pressure inside versus outside, which means understanding the maximum pressure it can handle is crucial.

- Rigid Stops: If rigid stops come into play, the extension and compression will be affected.

- Spring Rate: Spring rate is measured in pounds per inch, and it is the amount of force available to flex the bellows.

- Life Cycles: How long will the bellow have useful life? This will be specified as the number of life cycles, or flexing cycles.

- Temperature Extremes: This simply refers to the upper and lower extremes that the custom bellows can handle.

- Exposure: What media will this custom bellows be exposed to? Liquid or gas, or both? Will the exposure be to the inside or outside of the bellows? These pieces of information are vital. It is also important to identify potential corrosive conditions or agents.

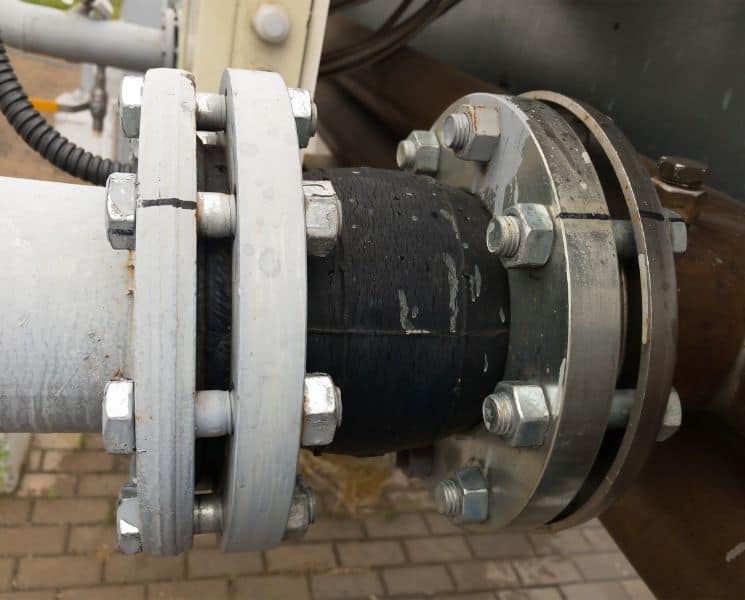

- Assembly Method: How will the bellows be joined to the end fittings once they are in place? It could be soldering, brazing, welding, or cementing.

- Vibration: The amount of vibration or shock that the bellows will experience during use should be specified.

- End Configuration: Do the bellows ends have to be a certain length and type? Probably, but since it’s custom, these configurations need to be specified.

- Geometric Constraints: If the bellows can only be a certain size to function properly in their application, that needs to be known.

If you are looking for custom bellows for a project you have, make sure to do your research so you know what you need. Contact us for the rest.