Some may see expansion joints as mere components, but they can be the unsung heroes of pipe assemblies by accommodating thermal expansion, vibrations, and other movements. However, even these resilient components can suffer when excessive vibrations come into play. Understanding why excessive vibration is bad for expansion joints is integral to maintaining the integrity and longevity of your pipelines.

Vibrations Can Damage the Bellows

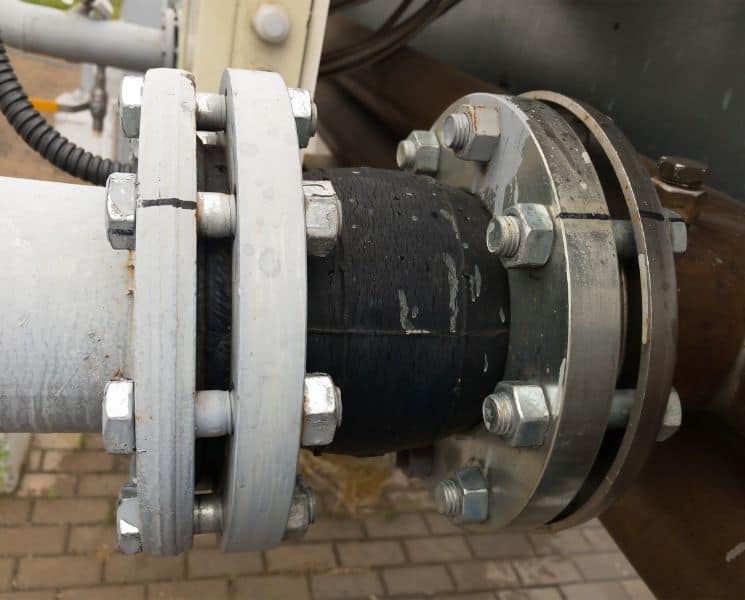

Manufacturers build the bellows within an expansion joint to withstand movements and protect the system’s structural integrity. While expansion joints are designed to handle a certain level of vibration, excessive vibrations can create significant stress. These can lead to material ruptures within the bellows, compromising the system’s safety and efficacy.

They Can Wear Out the Joint

Apart from damaging the bellows, another reason why excessive vibration is bad for expansion joints is that they can exhaust the component to the point that it prematurely reaches the end of its service life. That can result in unexpected failures in your pipeline or you having to install a new one sooner than you may have anticipated.

How To Prevent Vibration Damage

To prevent this damage from happening in your pipeline, make sure you are installing a component that is up to the task. For example, if you decide to use a metal expansion joint in your system, it is wise to ensure the joint and its bellows have the right design and construction. That will allow you to be certain that they can endure the vibrations they will experience in your pipe.

You can also proactively prevent vibration damage by examining your joint before installing it and frequently testing it afterward. That will ensure you add the proper part to your pipeline and allow you to catch any early warning signs of damage. You will help your company avoid costly failures, safety hazards, and shutdowns.

Triad Bellows is a world-class manufacturer of custom expansion joints and bellows for clients who need specific solutions for their pipelines. We have helped customers in multiple sectors solve their issues with durable components.