When engineering the pipeline mazes that form the lifelines for industries such as oil and gas, manufacturing, or wastewater treatment, it’s essential to account for variations in pressure that can affect them. These sectors often address this issue by incorporating expansion joints. However, it is important for designers to make considerations for expansion joint systems when creating these pipelines. Read below to learn more about the benefits of using expansion joints and what issues you should address when installing these components.

The Advantage of Expansion Joints

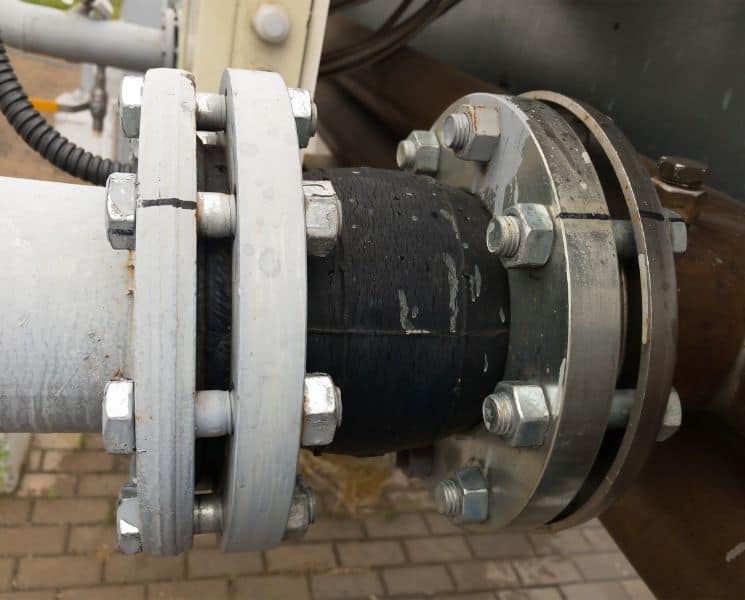

You may ask, “What are the advantages of using expansion joints when routing pipes?” Expansion joints offer flexibility over traditional pipe routing methods like bends or loops.

Since metals expand and contract with temperature fluctuations, expansion joints are vital in preventing stress and fatigue, which can lead to cracks or breaks in the pipeline. A well-chosen expansion joint compensates for thermal expansion and equipment vibration. The capacity to absorb directional movement sets them apart, as they can relieve system strain more efficiently than bends or loops, which take up more space and are less adaptable to unforeseen shifts in the environment.

Placement Is Key When Using Expansion Joints

One consideration to review when using expansion joint systems is whether you have positioned them correctly. It is advisable to install them near fixed anchors so that the pipe will place pressure on the joint. Otherwise, the pipe would experience the pressure, which could cause catastrophic failures and result in significant operational downtimes.

You must also ensure you have installed it where you or other engineers have enough room to perform proper expansion joint maintenance. If not, you may find it difficult to maintain or repair the joint so that it continues doing its job on the pipeline.

Ensure Proper Alignment in Your Installation

Another important consideration is whether the joint is properly aligned when you install it. Otherwise, it could result in an uneven distribution of force, leading to premature wear, leaks, or a complete joint failure.

Therefore, you must ensure you install the joint to the manufacturer’s specifications and have aligned it with the directional axis of the thermal movement it is meant to accommodate. Any deviation from this can undermine the system’s integrity and lead to performance issues that can be costly and complex to remediate.

Triad Bellows specializes in providing high-quality expansion joints to customers in the oil and gas industry, among many others. Our team specializes in delivering long-lasting products that will allow you to cut costs while keeping your pipelines running efficiently.