When looking at a pipeline, you’ll notice the different elements that come together and support its functionality. Expansion joints and couplings are beneficial devices that facilitate the transport of materials; however, it can be easy to confuse the two.

When comparing expansion joints to couplings, what’s the difference? Continue reading to learn more!

What Is an Expansion Joint?

Most metal expansion joints are highly engineered components with one or more metal bellows that absorb movements caused by thermal expansion or contraction. The bellows located within the mechanical device are flexible elements consisting of convolutions.

However, there are several other components that work together to promote an expansion joint’s functionality and efficiency. The other main elements are as follows:

Tie Rod

As the name suggests, an expansion joint’s tie rods are bars or rods that attach to the device’s assembly. Tie rods can absorb pressure loads and other forces like dead weight. These elements sometimes serve as limit rods to protect bellows from movements that can cause an anchor’s malfunction or failure.

End Connections

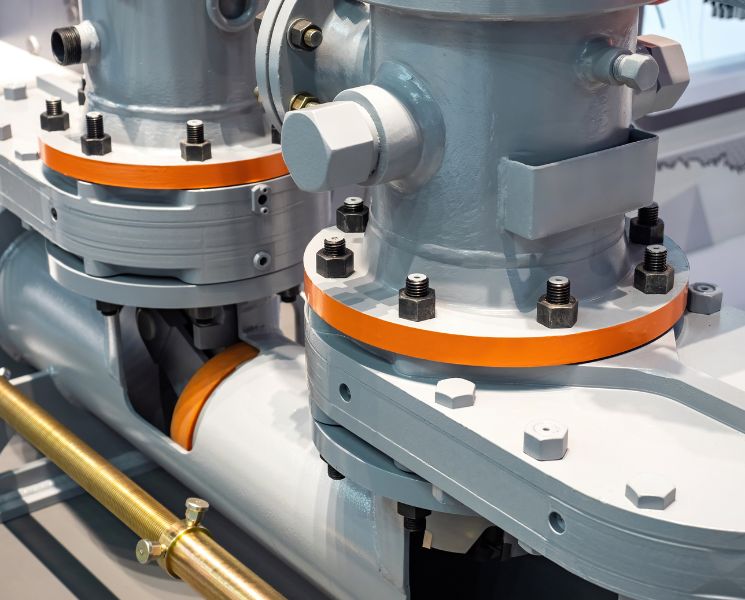

Expansion joints may include one of three different end connections: flanged end, Vanstone ends, and welded ends. Each variation can facilitate the installation of pipe infrastructure.

Protective Covers and Liners

Ideally, expansion joints would sit inside a metallic cover that protects the device from external sources. You would locate a liner within the device’s inner surface that helps mitigate the effects of flowing media.

When and How Do You Use an Expansion Joint?

Expansion joints are common elements in refineries, cryogenic plants, chemical and petrochemical plants, aerospace, and nuclear power plants. These components often serve various purposes in pipe infrastructure. For example, they relieve stress and strain on infrastructure, reduce vibration and mechanical noise within a pipeline, and help compensate for system misalignment.

What Is a Coupling?

A coupling is a device that joins two or more pipes to maintain continuity. The material used to create this component is similar to those used to construct the pipe infrastructure the coupling connects to. Depending on the infrastructure’s needs and the amount of movement it is subjected to, a pipe coupling may be rigid or flexible.

There are different categories of couplings that can serve a pipeline:

Removable

Removable couplings have a threaded style that facilitates the installation process onto infrastructure. These components have a wide base pipe segment and are sliced by a thread. The ends of a coupling are always threaded, with sealing tape finalizing the installation.

Permanent

Permanent pipe couplings typically use brazing or soldering. During the mounting and installation, permanent joints provide stability and sealing properties in the event of missing support.

When and How Do You Use a Coupling?

Couplings are helpful in facilitating changes in pipe routing, obstacle crossing, and wall penetration. Couplings are typically U- or elbow-shaped; however, they may include variants that feature different deflection angles. These components are incredibly beneficial in infrastructure that transports liquids, solids, steam, and air.

So, what’s the difference between expansion joints versus couplings? Expansion joints absorb vibrations and movement in the pipeline, while couplings facilitate pipe routing and design. While each component contributes differently to infrastructure, when used together, they can enhance pipeline design and function.

Triad Bellows is a trusted manufacturer and supplier of expansion joints and bellows. We are also a dependable resource for information involving expansion joint maintenance. For more information, please visit our webpage!