Metal expansion joints are critical components of piping systems in homes and buildings. While they have several applications in different industries, their purpose remains the same: they absorb vibrations and mitigate the consequences of thermal expansion and contraction.

However, equipment may not always function optimally, indicating potential issues in need of attention. Here are three tips for diagnosing your expansion joint problems that could help prevent damage to a pipe system.

Inspect Components for Leaks

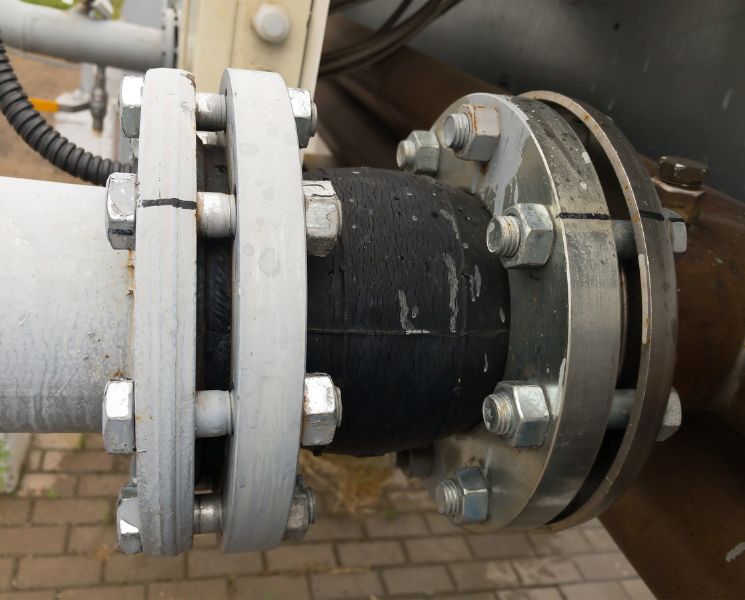

While expansion joints are sturdy, they may suffer damage in rare instances, resulting in leakage. A leak can compromise an entire pipe system and, depending on the material transferred, can cause severe consequences.

When inspecting for leaks, consider reviewing the entire component for gaps, cracks, and openings that promote leakage. You can also diagnose a leak while the pipe system is in use as you’ll hear, smell, or see material seeping through these openings.

Check for Deterioration

Pipe expansion joints have a typical service life of about 20 to 25 years. In this time, they’ll take on plenty of work! As components age, they may be prone to corrosion from accumulated moisture, so it helps to inspect joints for signs of rust, mold, or mildew.

Corroded expansion joints may appear and feel brittle to the touch and possess reddish-brown or orange coatings indicating rust.

Identify the Warning Signs

In a comprehensive system, identifying concerning areas can be challenging. However, you can typically identify additional warning signs by reviewing equipment before installation.

Signs of damage during shipping are usually present upon opening inventory; damaged components may have cracks, dents, and other markings that indicate problems. It also helps to inspect packaging upon receiving goods; ripped packaging can be a sign of mishandling.

When using these tips to diagnose your expansion joint problems, remember to test your pipe systems to ensure adequate functionality. Conducting regular tests and inspections also determines whether the equipment is up to code and quality standards.

Triad Bellows is a pipe expansion joint supplier and manufacturer that serves several industries nationwide. From power generation and construction to marine and wastewater treatment, our high-grade metal equipment can help support your projects. For more information on our services, please contact us through our website!