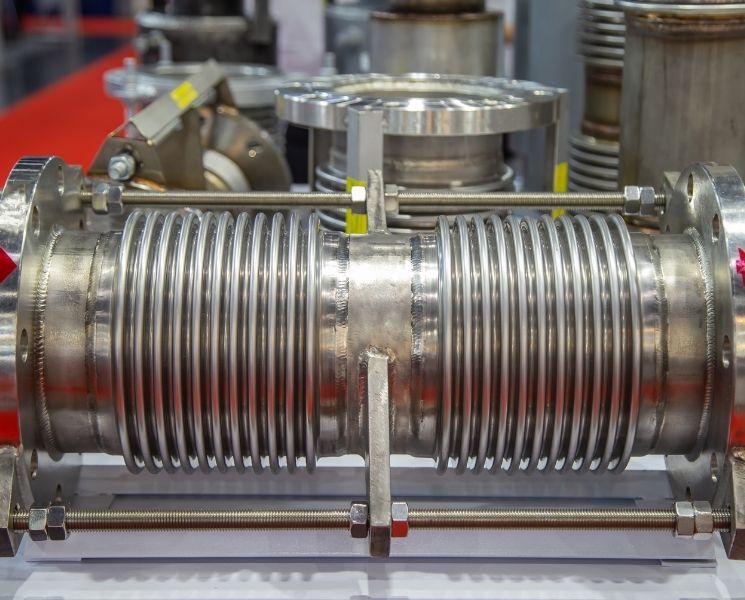

Metal expansion joints are an essential part of many piping systems. They reduce pipe stress, add flexibility, and permit movement that makes up for expansion and contractions resulting from environmental and temperature changes.

Metal expansion joints also include bellows that allow flexibility and movement. Pipes could crack or break under pressure and compromise your entire building and piping system without these critical components. Expansion joints are made to last 15 to 20 years with the correct design and installation, but sometimes, mistakes happen. Here are the common causes of corrosion in metal expansion joints.

Improper Installation

It’s crucial to properly install expansion joints in their correct locations because incorrect installation can cause corrosion in metal expansion joints. There’s an increased risk of failure and leakage if your expansion joints are installed incorrectly. The most common mistake is loose bolts and flanges causing leakage. Failure can also occur when joints with internal sleeves are installed in the opposite direction of flow and when bellows twist to make up for misalignments of the piping.

Damages From Transportation and Handling

Having the proper expansion joint maintenance, transportation, and handling is vital. Impairments like dents and deformation of the bellows can cause failure and corrosion in metal expansion joints. The impact from objects, tools, chains, or any surrounding constructions can damage expansion joints. Storing the materials incorrectly and having inadequate protection against weather conditions can damage metal expansion joints.

Deteriorating Bellows

The wrong choice of the bellows material to be in contact with fluid or external environmental conditions can cause corrosion in metal expansion joints and bellows. A common mistake is to use stainless steel bellows in the presence of chloride leaking from the insulation. We recommend you contact us to help you choose the appropriate materials.

Insufficient Pipe Support

It’s vital to use anchors and supports to hold the bellows in place. If they don’t have adequate support, expansion joints can move, which will cause failure. You should never compromise bellows to fit in their position because it will then compromise the performance of the bellows and your piping system.

There are many ways to prevent corrosion in metal expansion joints. If you’d like to learn more about bellows and expansion joints or need an expansion joint supplier, contact us at sales@triadbellows.com or use our contact form.