Mistakes To Avoid When Installing Expansion Couplings

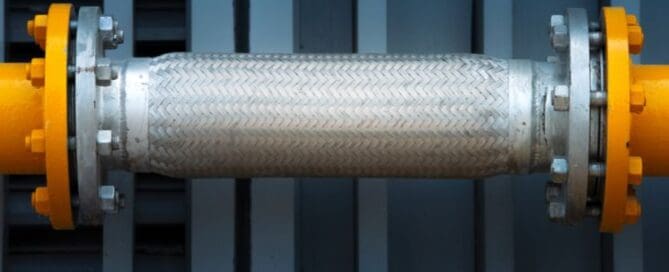

Expansion joints play an important role in maintaining the operations of a pipe, but so do other components, including expansion couplings. These parts help join two or more pipes together, allowing for the transfer of materials. Like expansion joints, it’s easy to make errors in their installation. Here are some mistakes to avoid when installing expansion couplings. Not Checking for a Misalignment One mistake you should avoid when installing couplings [...]