How do exhaust bellows and flex pipes differ? Since they both absorb movement, it can be difficult to understand the difference between the two. But knowing how each piece functions can help you make an informed decision on which is better for your application. In this blog, we’ll discuss the differences between flex pipes and exhaust bellows.

What Are Flex Pipes?

Flex pipes are flexible hoses that absorb high frequency, low amplitude engine vibrations. They’re made from a flexible material that’s typically a single ply of small grooves that give the material the ability to move from the vibration. But they don’t compress because of their design.

An external braid restrains the assembly; if this was compressed, it would swell and lose its ability to retain pressure. Flex pipes are a good choice for an application that only has vibrations.

What Are Exhaust Bellows?

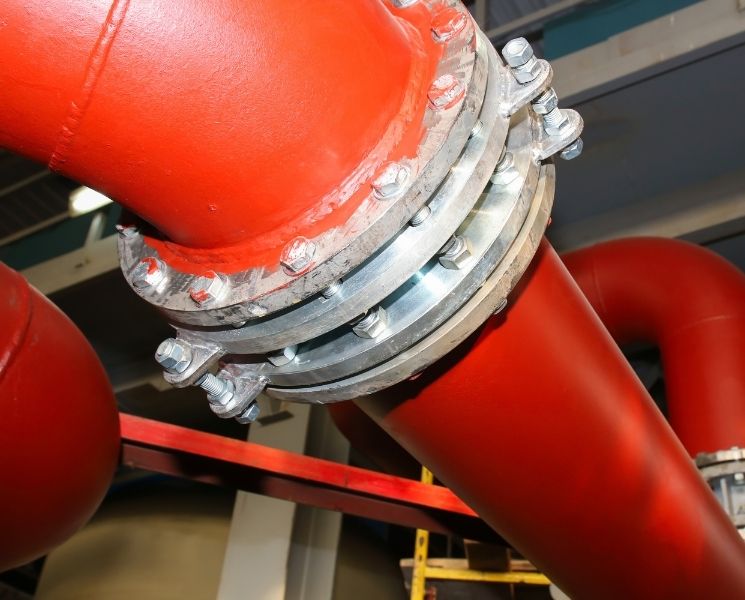

Exhaust bellows, also called expansion joints, absorb pipe expansion as well as vibrations. They have larger grooves, or corrugations, so they’re capable of compression. Exhaust bellows handle lateral movements to deal with issues like pipe misalignment. Plus, they are multi-ply, and despite being more compact, they are more durable and control vibrations better than flex pipes.

You can find exhaust bellows in single ply, but multi-ply bellows have more advantages despite their higher cost. They’re able to absorb more expansion and vibrations and are more reliable. Usually, exhaust bellows are a better choice for most industrial applications because of their ability to handle expansion and vibrations.

Find a Bellow Supplier

Want to learn more about how exhaust bellows and flex pipes differ? Contact us with any questions on how we can supply you with the best option. Triad Bellows is a bellow supplier that offers custom machining, so you’re sure to have the precise specifications that you need.

Our experts will follow your designs and suggest the best techniques and materials to ensure you have the most durable and long-lasting equipment. You can learn more about our forming techniques and installation process by exploring our blogs.